Hello all and welcome to my blog post.

I have been asking myself of late, in this modern world of gas and electricity why in earth do we love our real wood fires so much. I mean compared to other fuel types they are not controllable, as safe or even as efficient. Oh a lest not forget much less effort.

To answer this question we have to take a look at what bought us to 2017 from the days when we were merely evolved primates, Evolution. The skill to control fire is one that over hundreds of thousands of years has brought several advantages and has changed the way we have evolved.

- Heat. Heat is one of the key elements that we require for survival

- light. Having extra light means that we would have been more active and productive for longer.

- The ability to cook food and boil water. Importantly boiling water was the primary method of sterilisation for a milinium.

Tens of thousands of years ago, the human race was tribal. Generally Men would hunt and fight and woman would educate and gather. After several days hunting or gathering the first signs of the village would have been smoke from the fire, then as you drew closer the flickering light would be visible. This would be the first signs that you were home, that fire would have meant; food; safety, family,warmth and home. This instinct is still with us today if you walk into a public house with an open fire like a moth to a lantern you are drawn towards the flames. Maybe you return home to a lit stove, the infra red permiates your skin, the flame lights your face like a summers day and ? you know your home.

There is almost a life of its own within a wood fire, the very randomness of the flame caused by a million different variables from heat, to temperature to turbulence combine to make a flame that dances like a belly dancer crossed with a cloud hypnotising you and holding your gaze. This wood fired flame never becomes boring or tiresome and is ever more beautiful.

Finally as a race I think we like to control what we are afraid of. Fire can be most fearsome of thing, if you take a look a forest fires or a volcano we can only stand in awe powerless in their power. I would have a guess that when fire was first harnessed by a few that they were revered as almost god like. Gunpowder most certainly changed the world order.

And so a fire means many things to us on an instinctive primal level, there is still a little hunter gatherer in each of us although splitting a few logs is probably not the same as hunting a bear or maybe a sabre toothed tiger.

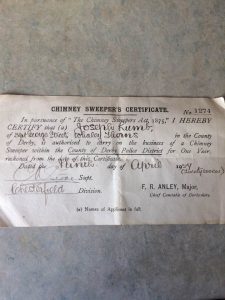

As a chimney sweep we do not have to understand the hidden psychological reasons why we are drawn to fire but if you are like me then you will be fascinated in all that encompasses our job including the hidden, the history and even the mythology.

I am not sure we have come as far as we like to believe from our humble beginnings as cave dwellers, just think fire works, a camp fire or maybe stone baked pizza.

I hope you have enjoyed my little insite into fire and that you take the time to like and share with your friends

Wishing you a happy and safe burning season

Daniel Hodgson

Recent Comments